Autonomous Supply Chains: The Future of Resilient Commerce

What are Autonomous Supply Chains

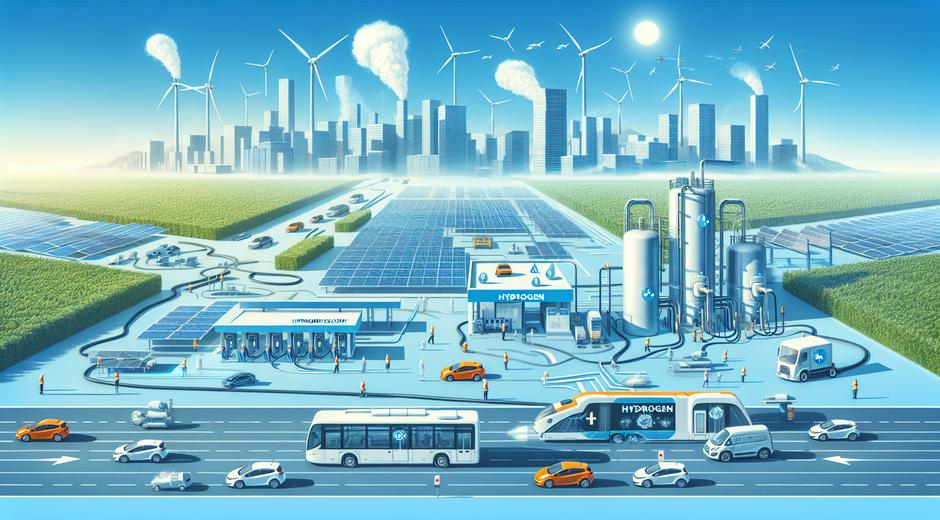

Autonomous supply chains are networks that use advanced software sensors robotics and decision making engines to manage flows of goods and information with minimal human intervention. These systems combine machine learning cloud computing internet of things and automation to deliver continuous visibility and adaptive responses across procurement production warehousing and logistics. The shift to autonomous supply chains is not just a technology upgrade. It is a strategic redesign that improves speed accuracy resilience and sustainability for companies of all sizes.

Why Autonomous Supply Chains Matter Now

Recent disruptions have revealed how fragile traditional supply chains can be. Companies that relied on manual processes or siloed systems found it hard to respond when demand patterns changed or transport networks had service interruptions. Autonomous supply chains change that dynamic by enabling rapid detection of issues and automated adjustments to routes inventory and production plans. This leads to fewer delays lower working capital and improved customer satisfaction. For publishers analysts and business leaders tracking global commerce trends the move toward autonomy is a major story that affects markets jobs and consumer prices. For ongoing coverage and analysis visit newspapersio.com.

Core Technologies That Power Autonomy

Autonomous supply chains rely on a set of complementary technologies that work together to sense decide and act. Key components include:

- Internet of things sensors that collect real time data on temperature location condition and handling

- Machine learning models that predict demand detect anomalies and recommend optimized plans

- Robotics and automated guided vehicles that handle picking packing and movement in warehouses

- Digital twin models that simulate networks and test responses without disrupting live operations

- Cloud based platforms that integrate data across partners and provide scalability

- Secure ledgers that record transactions and improve traceability across partners

These capabilities create a feedback loop where data fuels models and models inform robotic or system actions that change real world outcomes.

Benefits for Business and Society

Organizations that adopt autonomous supply chains can see multiple benefits across the value chain. Typical gains include faster order to delivery cycles better inventory turns and reduced waste from spoilage or expired stock. Autonomous systems also improve service levels by matching supply to demand more precisely which reduces stock outs and excess inventory.

On a societal level autonomous supply chains can boost economic resilience. When local networks can self adjust to disruptions fewer critical goods are delayed during emergencies. Environmental outcomes improve when routes and inventory are optimized to reduce fuel use packaging and product waste. Investors and regulators are increasingly attentive to these performance metrics which makes autonomy an important strategic priority.

Practical Steps to Build an Autonomous Supply Chain

Moving from manual or semi automated processes to autonomy requires a structured roadmap. Companies that rush to install devices without preparing data and governance often see slow returns. A practical pathway includes:

- Assess current data quality and integration capabilities across systems

- Define clear use cases that deliver measurable business value such as demand sensing or warehouse automation

- Start with pilot projects in controlled environments to validate models and governance rules

- Scale successful pilots by standardizing data formats APIs and operational playbooks

- Invest in change management and workforce reskilling so teams can operate with new tools

- Continuously measure outcomes and refine algorithms to achieve steady improvement

This staged approach reduces implementation risk and helps build internal confidence.

Common Challenges and How to Overcome Them

There are several adoption challenges to acknowledge. Data fragmentation across legacy systems can limit insights. Trust in automated decisions can be low among operations teams. Integration across trading partners can be slow because of inconsistent standards. To overcome these barriers organizations should prioritize data governance clear user interfaces explainable models and open APIs that enable partner collaboration. Leadership must also set measurable targets and invest in training that equips staff to supervise and intervene when needed.

Use Cases That Illustrate Impact

Real world examples show how autonomous supply chains create outcomes that matter. In manufacturing predictive maintenance helps avoid costly downtime by automatically scheduling repairs before failures occur. In retail autonomous replenishment systems analyze shelf level data to order stock in time for promotions. In cold chain logistics sensors monitor temperature and route changes are made automatically to protect perishable goods. Each use case reduces manual work and shifts human roles toward oversight optimization and strategy.

Measuring Success

To evaluate progress companies should track a small set of rigorous performance indicators. Common metrics include order cycle time inventory days of supply fulfillment rate and carbon emissions per unit delivered. Monitoring model accuracy time to detect anomalies and percentage of decisions executed automatically helps teams understand how much autonomy has been achieved. Benchmarking against peers and tracking trends over time informs investment priorities and course corrections.

Policy and Ethical Considerations

Autonomous supply chains raise policy and ethical questions that deserve public debate. Automation may change workforce needs which calls for proactive reskilling programs and social policies that support transitions. Data privacy and security are essential when sensitive partner information flows across platforms. Regulators and industry groups can support adoption by promoting standards that balance innovation with fairness and safety.

Looking Ahead

The path to widespread autonomy will be evolutionary not overnight. Advances in sensing connectivity compute and models will expand the scope of tasks that systems can perform reliably. As these capabilities scale businesses will be able to pursue more resilient localized networks and more efficient global flows. Thoughtful deployment will emphasize outcomes that are profitable scalable and responsible.

If you want resources that help leaders cultivate stronger focus and strategic thinking while navigating complex projects consider proven tools that support attention and decision quality. Learn more at FocusMindFlow.com.

Conclusion

Autonomous supply chains offer a powerful way to improve business resilience speed and sustainability. The promise is real but the journey requires clear strategy data readiness and human centered change programs. Organizations that align technology pilots with measurable business outcomes and develop transparent governance will lead the next wave of commerce innovation. As markets evolve those who invest wisely in autonomy will capture efficiency gains reduce risk and deliver better experiences for customers and communities.